AS1 is an innovative open-source humanoid robot designed for education, research, and hands-on innovation. Powered by the LegionAGI Framework, it integrates advanced neural control with modular sensor arrays, providing unparalleled balance, adaptability, and interactive capabilities.

Built using consumer-grade 3D printing and off-the-shelf hardware, AS1 is engineered to be replicable, affordable, and flexible. It serves not only as a platform for advancing robotics research, but also as a collaborative bridge between engineering and creative design.

By leveraging multi-agent systems and real-time learning, AS1 continuously adapts to new tasks and challenges. This marks a new era in robotics where machines are not only tools but intelligent partners capable of evolution.

Developed exclusively for the U.S. Military using military-grade components. Designed to secure immediate government funding for Legion ASI and serve as a life-saving replacement for human soldiers in future conflicts.

The AS1's neural architecture represents a revolution in accessible artificial intelligence—a digital mind that doesn't just process information but experiences its physical form through a rich sensory network. This distributed intelligence system combines the raw processing power of modern computing with biomimetic organization that enables both lightning-fast reflexes and sophisticated reasoning.

The AS1's cognitive center employs a hierarchical structure mirroring the human brain's organization, with specialized regions handling different aspects of robot function. This multi-layered approach creates a system where intelligence flows seamlessly from high-level reasoning to microsecond-precise motor control, all while maintaining awareness of the robot's physical state and environment.

Central Processing Hierarchy: The core intelligence flows through a sophisticated three-tier system that balances processing power with specialized function. The architecture begins with the NVIDIA Jetson Mini Super as the primary cortex, coordinating all subsystems through a comprehensive ROS 2 implementation that ensures seamless communication between cognitive and physical elements.

Distributed Intelligence Network: Rather than centralizing all processing, the AS1 implements a neurologically-inspired distributed system. This network distributes specialized processing tasks to dedicated controllers throughout the body, creating redundancy while enabling near-instantaneous responses to environmental changes without cortex intervention.

Sensory Integration Pathways: The sensory data processing model creates rich, multimodal awareness by fusing data from dozens of sensors into a coherent understanding of body position, environmental conditions, and physical interactions. These pathways ensure the robot maintains complete proprioceptive awareness at all times.

Gravity and Weight Perception System: A specialized neural pathway processes data from distributed force sensors, accelerometers, and load cells to create a comprehensive understanding of weight, balance, and gravitational forces. This system enables AS1 to precisely measure external loads, adapt to changing weight distribution, and maintain stability in varying gravitational conditions.

The AS1's brain leverages cutting-edge hardware to deliver unprecedented computational power in a humanoid platform. This sophisticated electronic nervous system combines powerful central processing with specialized co-processors that handle specific functions like motor control, sensory integration, and real-time balance maintenance.

Primary Processor - The Cerebral Cortex: The NVIDIA Jetson Mini Super serves as the central processing unit with capabilities far exceeding previous generations of robotics processors. Its 12-core ARM CPU cluster with dedicated AI accelerators delivers 24 TOPS of neural processing power, while 32GB LPDDR5 memory and 128GB NVMe storage provide ample resources for the LegionAGI framework to operate with minimal latency.

Secondary Processors - The Peripheral Ganglia: A distributed network of microcontrollers serves as local intelligence centers throughout the body. These STM32G4 series MCUs handle limb control with millisecond precision, each operating semi-autonomously to manage their assigned body segment while maintaining coordination with the central system through redundant communication channels.

Force and Weight Processing Unit: A dedicated co-processor specifically handles the integration of all weight, balance, and force sensing data. This specialized unit combines inputs from load cells, IMUs, and joint torque sensors to create a comprehensive model of weight distribution, gravitational forces, and balance conditions updated at 1000Hz for instant adaptation to changing conditions.

Software Architecture - The Digital Consciousness: The operation system architecture represents a revolutionary approach to robot cognition. Running Ubuntu with real-time kernel patches ensures deterministic responses, while the custom-compiled ROS 2 distribution optimized for humanoid control creates a robust framework for all robot functions. The Python + C++ hybrid orchestration layer bridges high-level cognition with low-level control systems.

The AS1's cognitive capabilities are powered by a revolutionary local language model implementation that brings true intelligence to an untethered platform. This sophisticated AI system operates autonomously while maintaining the capability to leverage cloud resources when available, creating a fluid intelligence that adapts to connectivity conditions.

Core Intelligence - The Digital Mind: The foundation of AS1's intelligence is a quantized 2.5B parameter model running entirely on-device. This model has been custom-trained on embodied robotics tasks with INT8 quantization for efficiency while maintaining reasoning capabilities. The token streaming rate of 15 tokens/second ensures responsive interaction without perceptible delays.

Model Architecture - Neural Organization: The transformer-based architecture has been optimized specifically for physical control tasks with innovations not found in standard LLMs. Its context window of 16K tokens provides extended environmental awareness, while special embedding layers for proprioceptive data integration allow the model to understand body position and physical feedback as part of its reasoning process.

Hybrid Processing - Adaptive Intelligence: The revolutionary aspect of AS1's intelligence is its ability to seamlessly transition between processing modes based on connectivity. The system dynamically switches between local and cloud models when network connectivity is available, gracefully degrading to essential functions when disconnected while maintaining core functionality regardless of connectivity state.

Weight and Force Reasoning Module: A specialized extension to the language model enables sophisticated reasoning about physical interactions. This module interprets data from the force and weight sensing systems, allowing AS1 to make inferences about object properties, estimate weights, predict balance requirements for new tasks, and verbalize its understanding of physical interactions in natural language.

The AS1's memory systems mirror human cognitive architecture, creating a sophisticated information management system that stores both immediate experiences and long-term knowledge. This multi-tiered memory structure ensures that relevant information is always accessible while maintaining efficient resource utilization.

Working Memory - Immediate Consciousness: The immediacy of experience is maintained through a 2GB dedicated LPDDR5 buffer for task processing. This system maintains a real-time sensory buffer with 30-second retention, creating a running record of recent experiences and sensory inputs that informs immediate decision-making and response generation.

Long-Term Memory - Experience Repository: Beyond immediate awareness, AS1 maintains persistent storage of learned behaviors and environmental maps. The hierarchical experience indexing system enables efficient retrieval of relevant past experiences, while redundant storage with corruption detection and repair ensures memory integrity over time. Cloud synchronization with differential updates minimizes bandwidth requirements while keeping knowledge current.

Procedural Memory - Movement Library: The robot's understanding of how to move and interact with objects is maintained in optimized storage dedicated to movement patterns and sequence chains. Hardware-accelerated recall enables sub-millisecond motion initiation, while the progressive refinement through reinforcement learning allows movement patterns to improve with practice. Cross-reference with declarative knowledge ensures contextual adaptation of movements to specific situations.

Gravitational and Force Memory: A specialized memory subsystem records and categorizes experiences related to weight, balance, and physical interactions. This system builds a comprehensive understanding of how different objects feel, how carried weights affect balance, and how to compensate for varying loads. This embodied knowledge grows continuously, allowing AS1 to make increasingly accurate predictions about physical interactions based on past experience.

The distributed control architecture of AS1 represents a revolutionary approach to robotic coordination, creating a system that combines central oversight with local autonomy. Like the human nervous system that enables both conscious control and reflexive responses, this sophisticated network maintains coordinated movement while providing instantaneous reactions to unexpected situations, creating fluid motion that adapts in real time to changing conditions.

The AS1 employs a revolutionary distributed control architecture that balances central intelligence with peripheral autonomy. This sophisticated network creates a resilient system capable of maintaining functionality even when individual components fail, while enabling both high-level coordination and low-level reflexive responses that don't require central processing.

Hierarchical Structure - The Neural Pathways: The control system is organized in a biomimetic hierarchy that mirrors natural nervous systems. Beginning with the central LLM Cortex that handles high-level planning, the system extends through the ROS 2 Communication Backbone to regional controllers for upper body, lower body, and sensory integration, before reaching the Per-Limb Control Units (PLCUs) that manage individual body segments.

Regional Controllers - The Spinal Segments: The intermediate layer of control provides regional coordination for major body sections. Each regional controller aggregates data from its assigned limbs and manages coordinated movements across multiple joints, while serving as a first-level fallback if communication with the central system is interrupted. These controllers also implement regional reflexes that don't require cortex involvement.

Balance and Load Distribution System: A specialized control subsystem integrates data from all weight and force sensors to create a comprehensive model of the robot's current load distribution. This system continuously calculates center of mass, predicts stability boundaries, and coordinates compensatory movements to maintain balance even when carrying uneven loads or operating on irregular surfaces.

Weight and Force Monitoring Network: A dedicated control pathway processes inputs from all load cells, force-sensitive resistors, and torque sensors throughout the body. This system creates a real-time map of all forces acting on the robot, enabling precise weight measurement of carried objects, detection of external forces like pushes or pulls, and appropriate compensation for changing load conditions.

Each major body section features its own semi-autonomous control unit that manages local function while coordinating with the broader system. These distributed controllers enable precise control of individual body segments while maintaining resilience through autonomous operation capabilities if central communication is interrupted.

Hardware Foundation - Local Intelligence Centers: The PLCUs are built around powerful microcontrollers that provide local processing capabilities for each major body segment. STM32G4 microcontrollers (STM32G474RE) or Teensy 4.1 for development operate at 170MHz with hardware floating-point units, providing sufficient processing power for complex local control algorithms while maintaining power efficiency.

Control Capabilities - Movement Precision: The heart of the PLCU's function is precise joint control with real-time adaptation. Each controller provides 16-bit precision position control at 1kHz update rate, while current sensing enables force estimation and collision detection. Adaptive PID algorithms with gain scheduling optimize control parameters based on operating conditions, while local trajectory smoothing and interpolation create fluid movement.

Force and Weight Integration: Each PLCU incorporates specialized circuits for processing local force and weight data before transmission to the central system. Load cells in extremities connect to HX711 24-bit ADCs for precise weight measurement, while FSRs provide tactile pressure data, and motor current sensing enables torque estimation. This integrated force awareness enables appropriate responses to physical interactions.

Autonomy Features - Independent Function: The robustness of the control system comes from the ability of each PLCU to function semi-autonomously when needed. Independent safety monitoring and collision avoidance operate even if central communication is lost, while self-diagnostics with fault detection and reporting ensure system health awareness. Sleep mode management conserves power during inactive periods.

The Balance Reflex System represents a groundbreaking approach to robotic stability, creating a subconscious motor layer responsible for dynamic postural correction, stability during motion, and fall prevention. Modeled after the human vestibular system and cerebellum, this module runs independently of high-level LLM logic and reacts in less than 10 milliseconds to external force or internal joint drift.

Core Components - The Balance Sensors: The foundation of the balance system is a comprehensive sensor network that provides complete awareness of position and forces. The primary IMU mounted at AS1's torso core (Bosch BNO085 or TDK ICM-20948) provides orientation and acceleration data, while foot load cells (4 per foot corner connected to HX711 ADCs) detect weight distribution, and joint angle sensors monitor limb positions.

Dedicated Processing - The Stability Brain: The balance system operates on a dedicated microcontroller that focuses exclusively on maintaining stability. A high-performance STM32G4 or STM32H7 runs a real-time balance loop that reads center of mass shifts from the IMU, compares expected versus actual joint loads, and monitors pressure deltas from load cells to detect imbalances before they become problematic.

Reactive Stabilization - The Instant Response: When the system detects an imbalance, it engages a sophisticated correction sequence without waiting for central control input. Limb joints execute micro-adjustments via PID loops, while posture is stabilized using inverse kinematics computed locally. The high-level Jetson LLM receives notification after the correction for contextual awareness, allowing it to incorporate the event into ongoing behavior planning.

Operational Modes - Contextual Balance: The balance system adapts its approach based on the robot's current activity to provide appropriate stabilization. Standing Mode focuses on vertical center of mass alignment, Walking Mode implements predictive foot placement with real-time correction, and Carry Mode adjusts posture based on external object weight distribution to maintain stability even with uneven loads.

The AS1 incorporates a revolutionary weight and force sensing system that provides comprehensive awareness of all physical interactions. This sophisticated network transforms the robot from a movement platform into a system that truly feels its environment, enabling precise weight measurement, force detection, and physical interaction awareness across the entire body.

Leg Weight Sensing System: The foundation of weight perception begins in the feet with high-precision load measurement capabilities. Four load cells with HX711 amplifiers are mounted under each foot (or under heel/toe segments), creating an 8-point pressure map that detects total body weight distribution, standing pressure, and weight shifts. This system enables detection of dynamic weight shifts during walking or squatting, terrain feedback for surface adaptation, and balance correction based on pressure distribution.

Arm and Hand Force Detection: The manipulation capabilities are enhanced through sophisticated force sensing in the upper limbs. Force Sensitive Resistors (FSRs) or mini load cells mounted in the palms and fingers detect gripping force and inferred object weight, while wrist joint sensors combine with IMU data to measure static holding weight based on torque and angle, and estimate object inertia during movement for adaptive handling.

Torso Load Detection: The central body incorporates its own force sensing to detect external loads and interactions. Piezoelectric film sensors or Flexiforce sensors mounted behind the chest panel or inside torso padding detect backpack weight, pressure from someone leaning on AS1, or loads applied to the chest/front from tools or carried objects, creating awareness of forces across the entire body.

Joint Torque Estimation: The most sophisticated aspect of the weight sensing system leverages the motor drivers themselves as force sensors. Many motor drivers (VESC, ODrive, TMC5160) offer real-time motor current monitoring and torque estimation, allowing the system to infer loads based on the effort required to maintain position. This capability enables estimating object weight during movement, implementing adaptive grip strength, and protecting joints from overload.

The control architecture provides multiple interfaces for development, monitoring, and customization, creating a system that can be easily programmed, monitored, and modified. These interfaces make the sophisticated control system accessible for both development and operational oversight.

Development Interfaces - Builder Access: The system provides comprehensive access points for programming and testing during development. USB debug connections to each PLCU enable direct programming and monitoring, while JTAG/SWD headers provide real-time debugging and trace capabilities for detailed analysis. The serial console access for diagnostic output and force-feedback test mode for actuator validation make development and testing straightforward.

Operational Monitoring - System Oversight: During operation, comprehensive real-time monitoring enables complete awareness of system state. Real-time telemetry streaming via ROS 2 topics provides continuous data on all aspects of operation, while the web-based dashboard for system status visualization makes this information accessible and comprehensible. Anomaly detection with configurable alerting thresholds brings attention to potential issues before they become problems.

Bio-Display Integration: The control system integrates directly with the circular LCD displays located at major joints and along limbs, providing visual feedback of system state directly on the robot's body. These displays show real-time force, weight, balance, and status information, creating an externally visible representation of the robot's internal state that serves both diagnostic and aesthetic purposes.

Customization Pathways - System Expansion: The open architecture enables straightforward customization and expansion of capabilities. Python APIs for high-level behavior programming, ROS 2 node templates for component development, and YAML-based configuration for system tuning make it easy to modify behavior. The behavior tree editor for complex sequence creation enables sophisticated behavior programming without low-level coding.

The AS1's communication architecture represents a revolution in robotic networking, creating a resilient, multi-layered system that ensures critical information reaches its destination regardless of operating conditions. Like the human nervous system that uses multiple signaling pathways to maintain function even when individual neurons fail, this sophisticated network combines high-speed primary channels with redundant backups to create uninterrupted information flow from sensors to processors and from decision centers to actuators.

The backbone of the AS1's internal communication is a robust, automotive-grade network system that provides reliable, deterministic messaging across all subsystems. This industrial-strength communication backbone ensures critical control information reaches its destination with guaranteed timing, even in challenging electromagnetic environments.

CAN FD Network - The Digital Spine: The foundation of the communication system is a high-reliability controller area network using the latest CAN FD protocol. Operating at 5Mbps with prioritized message arbitration, this differential signaling system provides exceptional noise immunity in high-EMI environments. Redundant physical pathways through limb segments ensure communication can reroute around damaged sections, while hardware-level message filtering and acceptance masking optimize bandwidth utilization.

Physical Implementation - Robust Connections: The communication hardware is engineered for reliability in challenging conditions. Twisted pair cabling with shielding provides EMI protection, while MCP2562FD CAN FD transceivers with standby mode support enable power-efficient communication. The star-topology distribution with intelligent repeaters optimizes signal integrity, and termination resistors in removable connectors facilitate easy service when needed.

Force and Weight Data Protocol: A specialized high-priority message format ensures that critical force and weight information is transmitted with minimal latency. This protocol enables real-time awareness of changing load conditions, with prioritized arbitration ensuring these messages take precedence over routine traffic. The data format includes calibrated values, raw sensor readings, and derived metrics like center of pressure and estimated object weight.

Protocol Features - Communication Intelligence: The sophisticated protocol implementation ensures reliable information transfer under all conditions. Priority-based arbitration guarantees critical messages reach their destination first, while automatic retry mechanisms handle transmission failures without application intervention. The 29-bit extended identifier support provides an expanded address space for the complex robot structure, and hardware-accelerated CRC checking ensures data integrity.

Multiple backup communication channels ensure resilience against failures, creating a system that maintains essential function even when primary pathways are compromised. This multi-layered approach provides both redundancy and specialized channels optimized for different types of data transfer.

UART Fallback - The Emergency Channel: When the primary bus is unavailable, the system automatically transitions to backup serial connections between adjacent subsystems. Operating at 3Mbps with a simple packet protocol that includes checksumming, this system provides sufficient bandwidth for basic command and control functions. The automatic failover activates without central coordination, maintaining essential operation through a basic command set for emergency functions.

I2C Inter-Joint Connections - Local Coordination: For communication between closely positioned components, the I2C bus provides an efficient secondary pathway. Operating at 400kHz for sensor aggregation with a standardized register map across all controllers, this system enables efficient local data sharing. The multi-master capability supports peer-to-peer communication without central coordination, while clock stretching accommodates resource-constrained operations.

Weight and Force Fast-Path: A dedicated communication channel provides ultra-low latency transmission of critical force and weight data directly to the balance control system. This specialized pathway bypasses normal message routing to ensure that destabilizing force changes are detected and addressed within milliseconds, preventing falls or load imbalances before they develop into critical situations.

High-Bandwidth Channels - Rich Data Transfer: For information types that require significant data throughput, dedicated high-capacity channels provide the necessary bandwidth. Gigabit Ethernet handles vision processing and audio data, while USB 3.0 interfaces enable high-capacity data transfer for system updates and logging. MIPI CSI connections support direct camera integration, and an HDMI output is available for external monitoring during development.

The AS1 maintains persistent connection to the outside world through multiple wireless channels, ensuring continuous communication capabilities regardless of environment. This sophisticated wireless architecture enables remote monitoring, control, and intelligence augmentation while maintaining security and privacy.

Cellular Communication System - Global Connectivity: The integrated cellular modem provides connectivity anywhere with cellular service, freeing the robot from dependency on local networks. The Quectel EG25-G 4G LTE modem with standard SIM card slot supports comprehensive frequency coverage across LTE FDD (B1/B3/B5/B7/B8/B20/B28), LTE TDD (B38/B40/B41), WCDMA (B1/B5/B8), and GSM (B3/B8) bands. Maximum downlink of 150Mbps and uplink of 50Mbps provide ample bandwidth for remote operation and intelligence augmentation.

Local Wireless - Environmental Integration: For connectivity within local environments, the AS1 supports multiple short-range wireless standards. WiFi 6 (802.11ax) with 2.4GHz and 5GHz support provides high-bandwidth local connectivity, while Bluetooth 5.2 with LE Audio capabilities enables peripheral connections and audio streaming. Additional support for Thread/Zigbee smart home integration and Ultra-wideband (UWB) precision positioning creates comprehensive awareness of and interaction with connected environments.

Telemetry and Force Data Streaming: A specialized data channel continuously transmits force, weight, and balance information to monitoring systems, enabling remote awareness of the robot's physical interactions. This stream includes real-time data on object weights being manipulated, external forces being applied to the robot, and current balance conditions, providing complete visibility into physical interactions even from remote locations.

Security Features - Protected Communication: All wireless communication incorporates comprehensive security measures to protect both the robot and the data it transmits. Hardware-accelerated encryption secures all wireless traffic, while certificate-based authentication ensures only authorized systems can access services. The secure boot pathway for wireless subsystems prevents firmware tampering, and RF power management minimizes emissions when not in use to reduce both power consumption and detectability.

An intelligent management layer ensures optimal use of available communication channels, automatically routing information through the most appropriate pathway based on priority, bandwidth requirements, and channel availability. This sophisticated orchestration creates a self-optimizing network that maximizes both reliability and efficiency.

Dynamic Routing - Intelligent Path Selection: The communication management system continuously monitors all available channels and selects the optimal path for each message type. Real-time path selection based on message priority and channel availability ensures critical information always takes the fastest route, while bandwidth allocation according to operational requirements optimizes resource utilization. Automatic fragmentation and reassembly of large messages enables efficient transfer of data that exceeds individual packet size limits.

Failover Logic - Continuous Operation: Sophisticated monitoring and recovery mechanisms maintain communication even when individual channels fail. Continuous channel health monitoring detects deteriorating connections before they fail completely, while seamless transition between communication methods occurs without data loss when failures do occur. Store-and-forward buffering preserves messages during intermittent connections, and prioritized message queuing ensures the most important information gets through during limited connectivity.

Weight and Force Transmission Prioritization: The communication orchestration system gives special priority to messages containing force, weight, and balance information, ensuring this safety-critical data always reaches its destination with minimal latency. Dedicated queues with preemptive priority ensure these messages are transmitted ahead of routine traffic, while special error detection and correction protocols provide additional reliability for this crucial information.

Synchronization - Coordinated Timing: Precise timing coordination across all systems ensures consistent operation and accurate data correlation. The precision time protocol implementation synchronizes all subsystems to a common time base with sub-microsecond accuracy, while distributed clock recovery mechanisms maintain timing stability even when the primary time source is unavailable. Temporal message sequencing preserves causality in distributed processing, ensuring events are processed in the correct order regardless of transmission delays.

The AS1's power architecture represents a revolution in energy management for autonomous robots, creating a system that combines high energy density with intelligent distribution and dynamic optimization. Like the human circulatory system that delivers oxygen and nutrients precisely where they're needed, this sophisticated power network provides carefully regulated energy to every subsystem while adapting to changing demands, ensuring maximum operational time while maintaining both safety and performance.

The AS1 employs a revolutionary modular power system that maximizes runtime while ensuring safety and reliability. This sophisticated energy storage solution combines advanced battery chemistry with intelligent management to create a power source that's both high-capacity and adaptable to changing operational needs.

Battery Technology - The Power Core: The heart of the power system is a high-capacity LiFePO4 battery pack that combines safety with performance. The 24V 10000mAh primary pack uses chemistry selected specifically for safety, cycle life, and power density, providing over 2000 cycles at 80% depth of discharge. The flame-retardant electrolyte formulation enhances safety, while the wide operating temperature range (-20°C to 60°C) ensures functionality in varied environments. Peak discharge capability of 15C (150A) provides ample power for dynamic movements.

Battery Management - Intelligent Oversight: A sophisticated monitoring and protection system ensures optimal battery performance and longevity. Active cell balancing with charge redistribution maintains uniform energy distribution across cells, while temperature monitoring at 12 points within the pack detects hotspots before they become dangerous. State-of-charge estimation using multiple algorithms (Coulomb counting with temperature compensation, open-circuit voltage mapping, impedance tracking, and machine learning prediction) provides accurate runtime estimation under all conditions.

Weight and Force Impact Management: The power system includes specialized monitoring for movements that create high momentary power demands. Load-based power allocation intelligently provides additional energy to motors experiencing high resistance due to carried weights or external forces, while predictive algorithms anticipate power needs based on detected object weights and planned movements to prevent brownouts during high-load operations.

Modular Architecture - Flexible Power: The revolutionary aspect of the power system is its ability to adapt to different runtime requirements through modular batteries. The hot-swappable design enables battery replacement without shutting down, while magnetic connectors with arc prevention make swapping safe and simple. Automatic capacity detection and runtime estimation provide accurate operational forecasting, and parallel operation capability allows extended runtime for demanding applications.

Intelligent power management ensures efficient energy use across all systems, delivering precisely regulated power to each component while monitoring consumption and protecting against faults. This sophisticated distribution system creates an efficient, reliable power network that maximizes runtime while ensuring safety.

Distribution Architecture - Power Pathways: The hierarchical power delivery system creates an efficient power network with prioritized subsystems. Isolated converter stages provide noise immunity between sensitive electronics and high-power motors, while the multi-rail output system delivers precisely regulated voltage to each subsystem: 24V for actuators, 12V for high-power sensors, 5V for control logic, 3.3V for low-power sensors, and 1.8V for digital core components.

Protection Features - System Safeguards: Comprehensive protection mechanisms ensure reliable operation and prevent damage from electrical faults. Electronic circuit breakers with configurable trip points protect against overcurrent conditions, while inrush current limiting prevents power spikes during startup. Additional safeguards include reverse polarity protection, transient voltage suppression, EMI filtering on all power rails, and thermal monitoring with automatic throttling to prevent overheating.

Force and Motion Power Management: The distribution system includes specialized circuits that dynamically adjust power allocation based on detected forces and planned movements. High-current pathways with priority routing ensure motors receive sufficient power when lifting heavy objects or resisting external forces, while predictive power allocation anticipates needs based on the weight sensing system's measurements and planned motions to prevent brownouts during demanding operations.

Intelligent Control - Energy Optimization: A dedicated microcontroller orchestrates the entire power system for maximum efficiency and reliability. The STM32G0 controller handles power sequencing during startup and shutdown, while continuous power profiling enables consumption analysis and optimization. Scheduled power cycling for system maintenance extends component life, and load shedding during low battery conditions preserves critical functions. The brown-out prevention with graceful shutdown ensures data integrity during power loss.

The AS1 platform includes innovative approaches to energy recovery and external charging, maximizing operational time while providing flexible recharging options. These systems extend runtime while making the robot more adaptable to different operational environments and use cases.

Regenerative Braking - Energy Recovery: An innovative system captures energy that would otherwise be lost during deceleration and converts it back to electrical power. This regenerative braking system uses bidirectional motor drivers with regeneration capability to recover energy during movement deceleration, while a supercapacitor buffer provides temporary storage for the captured energy. Adaptive control algorithms maximize recovery efficiency by optimizing braking profiles based on motion parameters and battery state.

Weight-Based Energy Management: The AS1 implements a sophisticated power optimization system based on detected weights and forces. When carrying heavy objects, the system automatically adjusts power allocation, movement speed, and posture to minimize energy consumption while maintaining stability. This weight-aware energy management extends battery life during load-carrying operations by optimizing movements specifically for the detected weight distribution.

External Charging - Power Replenishment: Flexible charging options make the AS1 adaptable to different operational environments and usage patterns. Wireless charging pad compatibility enables convenient no-contact power replenishment, while USB-C PD support up to 100W provides fast charging from standard power supplies. The dedicated charging port with magnetic connection ensures reliable connection while preventing damage from accidental disconnection during charging.

Power Monitoring - Energy Awareness: Comprehensive monitoring provides complete visibility into energy usage patterns and trends. Energy usage tracking per subsystem identifies power-hungry components, while consumption profiling by movement type helps optimize motion patterns for efficiency. Runtime prediction based on usage patterns provides accurate operational planning information, and efficiency analysis with optimization suggestions helps users maximize battery life through behavior adjustments.

The AS1's physical structure represents a revolution in 3D-printable robotics, creating a system that combines strength, precision, and aesthetic appeal in a buildable platform. Like the human musculoskeletal system that enables both powerful movements and delicate manipulation, this sophisticated mechanical architecture provides a perfect balance of structural integrity and articulation, creating a platform capable of fluid, coordinated motion while maintaining the durability needed for practical applications.

The AS1's frame represents a revolutionary approach to 3D-printable robotics, creating a structure that maximizes strength and durability while minimizing weight and print complexity. This innovative design makes advanced robotics accessible to individual builders while maintaining professional-grade performance capabilities.

Frame Design Philosophy - Structural Intelligence: The biomimetic structure takes inspiration from human skeletal systems while optimizing for the unique capabilities of additive manufacturing. Generative design algorithms create optimized internal structures that place material exactly where it's needed for maximum strength-to-weight ratio, while stress-oriented material distribution ensures durability under load. The unified mounting system simplifies assembly by providing standardized attachment points for all components.

Material Selection - Optimized Composition: Each component uses materials specifically chosen for its functional requirements and print characteristics. The primary structure employs carbon fiber-reinforced PETG (CF-PETG) with 25% carbon fiber content for exceptional rigidity and a heat deflection temperature of 89°C. This material's tensile strength of 65 MPa provides excellent durability, while optimized print parameters (245-255°C print temperature, 80-90°C bed temperature, 0.2mm layer height, gyroid infill at 40% density) ensure consistent results.

Force Management Channels: The structural design incorporates specialized pathways for force distribution and load bearing. Reinforced channels in the arms, legs, and torso distribute forces from carried weights across the entire structure rather than concentrating them at attachment points. These load-bearing pathways mimic the force distribution mechanisms in human skeletons, enabling the robot to safely handle weights that would damage conventional designs.

Weight and Force Sensing Integration: The structural elements are designed with specific mounting points and channels for the comprehensive weight and force sensing system. Load cell mounting points in the feet provide stable, calibrated weight measurement, while cavities for force-sensitive resistors in the hands enable precise grip force control. The chest panel incorporates mounting points for pressure sensors, and structural elements include passages for sensor wiring throughout the body.

The AS1 features a comprehensive 37-degree-of-freedom design for human-like movement capabilities, creating a platform capable of both powerful movements and subtle gestures. This sophisticated articulation system combines precision engineering with biomimetic design to create natural, fluid motion across the entire body.

Articulation Distribution - Movement Architecture: The degrees of freedom are distributed throughout the body to enable both expressive communication and functional capability. The head's 3 DOF (pan, tilt, roll) enable natural directional focus and communicative gestures, while the neck's 2 DOF provide additional flexion/extension and rotation for lifelike movement. The torso's 2 DOF allow forward/backward tilt and rotation, creating a dynamic core that serves as the foundation for upper body expressiveness.

Primary Actuators - Power Centers: The major joints that handle the highest loads use sophisticated brushless DC motors with field-oriented control for maximum power and efficiency. Operating at 24V with 120W peak power output, these motors incorporate inline planetary gearboxes with 10:1 reduction for optimal torque multiplication. Dual magnetic encoders (pre and post gearbox) provide comprehensive position feedback, allowing precise control with position resolution of 0.01° while delivering peak torque of 12Nm.

Force-Aware Control Systems: Each motor incorporates specialized control algorithms that adapt to detected weights and forces. When AS1 is carrying objects or experiencing external forces, the control system automatically adjusts power delivery, movement speed, and position control parameters to maintain precision while preventing damage. This load-adaptive control ensures consistent performance regardless of the forces being experienced during operation.

Secondary and Tertiary Actuators - Graduated Power: The graduated actuator approach allocates power appropriate to each joint's requirements, optimizing both performance and efficiency. Secondary joints (elbows, knees) use 80W BLDC motors with harmonic drive gearboxes for high precision with less power, while tertiary joints (wrists, ankles, head) employ 20W digital servo motors with embedded controllers for efficient operation of lighter-duty movements. The smallest quaternary joints (fingers, facial expression) use micro servo motors that balance dexterity with power efficiency.

Sophisticated motor control enables fluid, coordinated movement across all joints, creating natural motion that mimics biological systems. This control architecture transforms raw mechanical capabilities into graceful, purposeful movement while maintaining precise control under varying load conditions.

Control Methodology - Movement Intelligence: The distributed position-velocity-torque control system creates coordinated, natural motion across the entire robot. Cascaded PID loops with feed-forward compensation provide precise position control while anticipating required forces, while anti-windup protection prevents controller saturation during extended operations. Velocity profiling with trapezoidal acceleration and jerk limitation creates smooth movement transitions that appear natural rather than mechanical.

Motor Driver Technology - Power Intelligence: Custom-designed FOC driver boards form the interface between control signals and physical movement. Using DRV8305 gate drivers and DrMOS integrated power modules, these sophisticated controllers provide precise power delivery with comprehensive protection. Current sensing through in-line shunt with differential amplification enables accurate torque estimation, while the 20kHz PWM frequency with dead-time insertion ensures efficient motor operation with minimal noise.

Weight and Force Adaptation: The movement control system continuously adjusts parameters based on detected weights and forces to maintain precision under varying loads. When carrying objects or experiencing external forces, the system automatically modifies acceleration profiles, movement speeds, and control loop parameters to maintain stability and precision. This adaptive control ensures consistent performance regardless of the physical forces acting on the robot.

Position Sensing - Location Awareness: Accurate knowledge of joint position forms the foundation of precise movement control. The AS14's primary encoder system uses AS5048A 14-bit magnetic rotary encoders for high-resolution position feedback, while secondary feedback from motor current provides torque estimation. Absolute position tracking with battery-backed reference maintains calibration across power cycles, while auto-calibration routines at startup ensure consistent operation.

The AS1's motion control system creates natural, human-like movement through sophisticated control algorithms and pre-programmed patterns. This biomimetic approach transforms mechanical actuation into fluid, purposeful motion that appears natural rather than robotic, creating more intuitive human-robot interaction.

Gait Generation - Natural Walking: The walking system implements sophisticated algorithms that create stable, natural bipedal locomotion. Zero Moment Point (ZMP) calculation ensures dynamic stability throughout the walking cycle, while center of mass trajectory planning with stability margins prevents falls even during rapid direction changes. Foot placement optimization enables adaptation to uneven terrain, and energy-minimal walking patterns maximize efficiency during extended movement.

Load-Adaptive Movement: The movement system automatically adjusts patterns based on detected weights and load distribution. When carrying objects or experiencing uneven weight distribution, gait patterns, posture, and balance strategies automatically adapt to maintain stability while minimizing energy consumption. This weight-aware movement intelligence enables safe navigation even when carrying significant or unbalanced loads.

Gesture Library - Expressive Communication: Beyond functional movement, the AS1 incorporates a comprehensive library of natural gestures for non-verbal communication. These pre-programmed movement patterns can be parameterized for customization, allowing emotionally expressive body language appropriate to different situations. Cultural variation support ensures appropriate signaling across different contexts, while context-aware gesture selection automatically chooses gestures that complement verbal communication.

Mimicry Capabilities - Learning Through Observation: One of the most revolutionary aspects of the AS1's movement system is its ability to learn new movements by watching humans. Visual analysis of human movement enables replication through inverse kinematics solving for pose matching, while motion capture through standard camera input facilitates the acquisition of new movement patterns. The progressive learning system refines observed movements through practice, while style transfer adapts human examples to the robot's unique embodiment.

The AS1's perception architecture represents a revolution in robotic sensing, creating a comprehensive awareness of both the environment and the robot's own physical state. Like the human sensory system that combines vision, hearing, touch, and proprioception into a unified understanding of the world, this sophisticated network of sensors creates a rich, multi-modal perception that enables natural interaction, precise manipulation, and adaptive behavior in changing conditions.

The AS1's visual perception enables detailed environmental understanding through a sophisticated multi-camera system with advanced processing. This comprehensive visual awareness forms the foundation for navigation, object recognition, and human interaction, creating a robot that truly sees and understands its surroundings.

Hardware Components - The Eyes: The vision system employs multiple specialized cameras that work together to create comprehensive visual awareness. The primary camera module using Sony IMX477 sensor ($95) provides high-resolution imaging with excellent low-light performance. This main visual input is supplemented by a depth sensing Time-of-Flight (ToF) VL53L8CX sensor array that provides 8×8 measurement zones with range up to 4 meters, while a wide-angle fisheye lens module with 180° field of view enables peripheral awareness for navigation and obstacle avoidance.

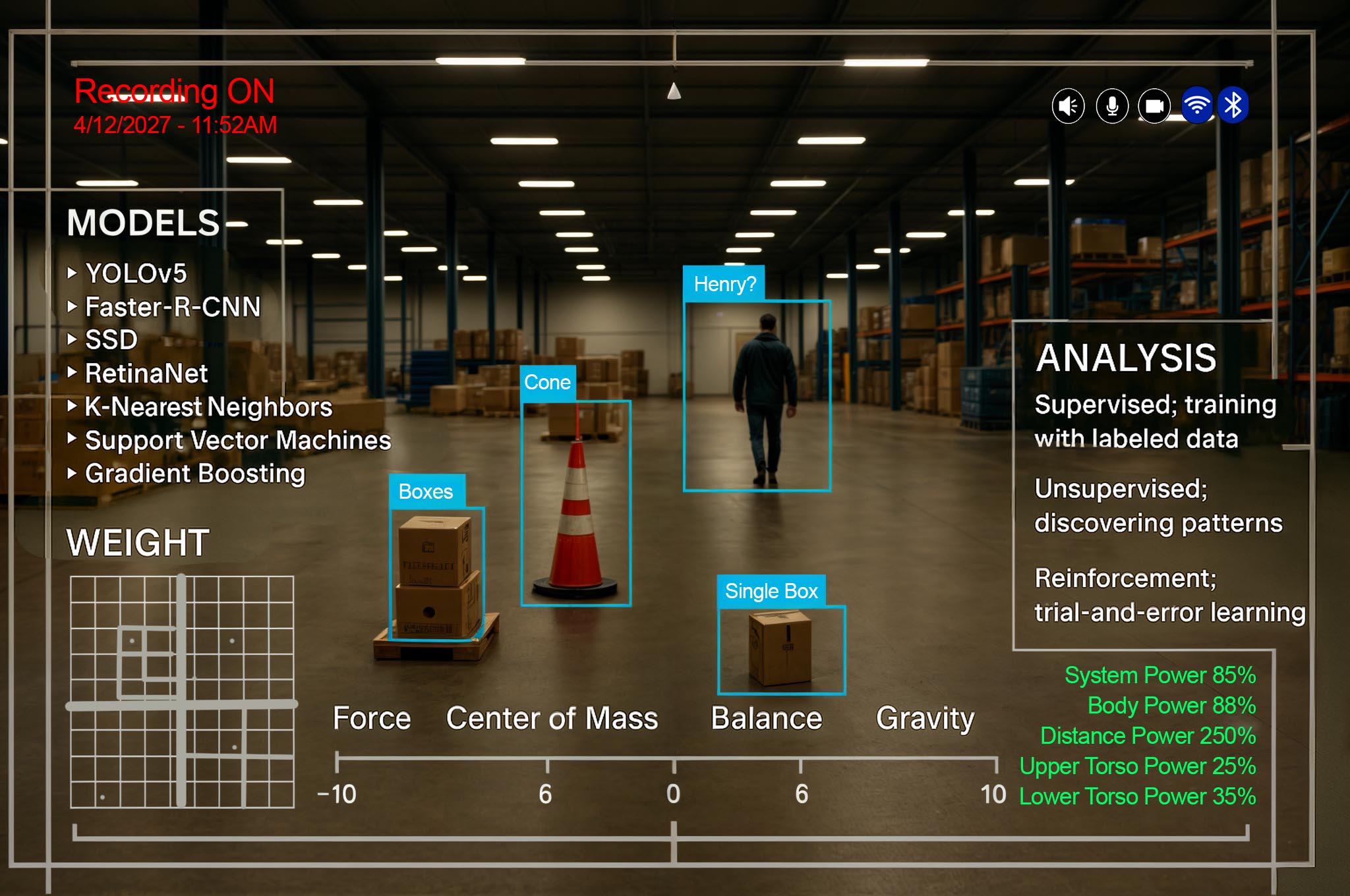

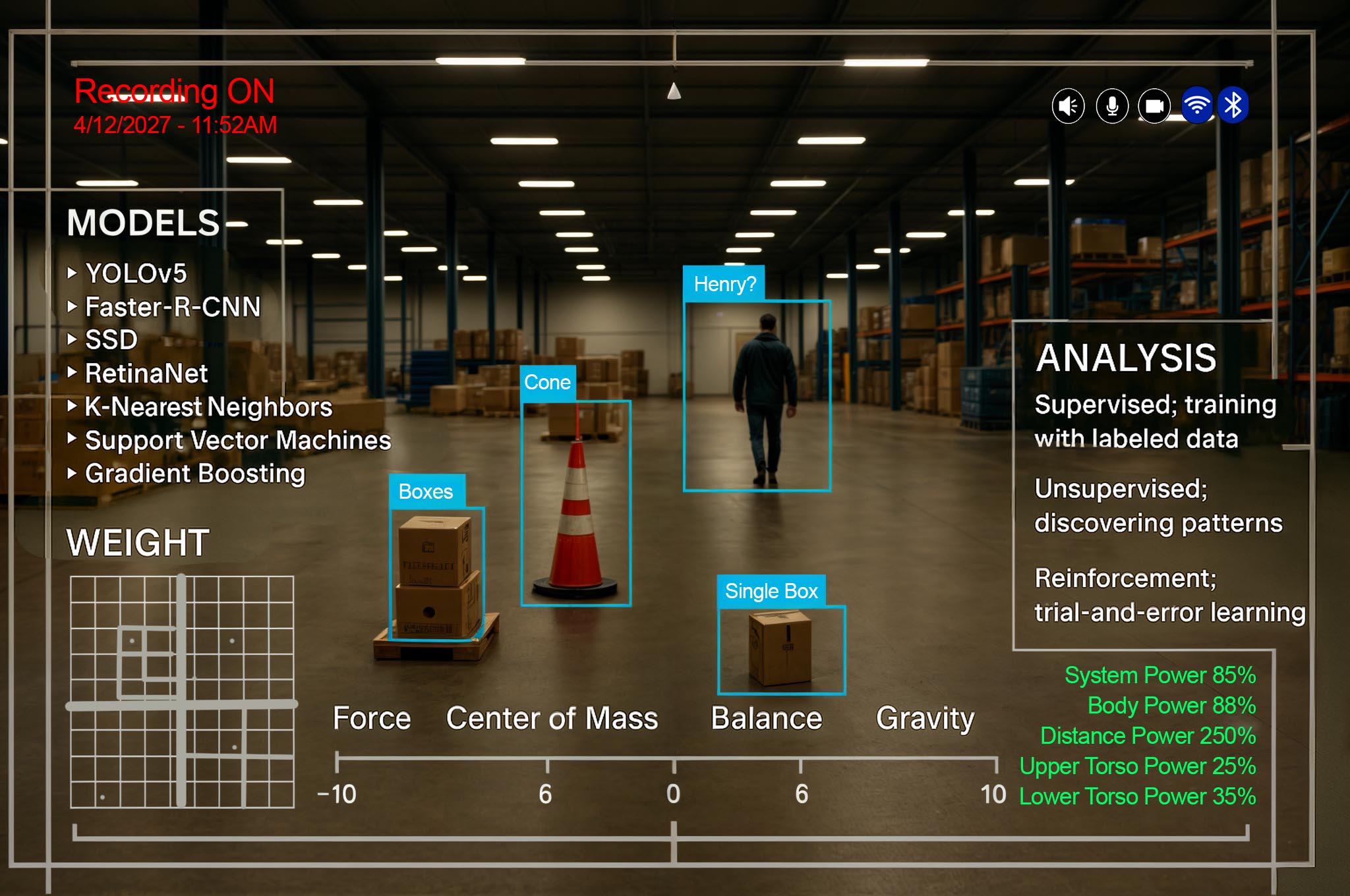

Visual Processing Pipeline - Image Understanding: Raw visual data is transformed into meaningful perception through a sophisticated processing sequence. Hardware-accelerated image preprocessing handles distortion correction, color normalization, dynamic range compression, and noise reduction to optimize image quality before analysis. The object detection and tracking system identifies up to 50 object classes simultaneously while maintaining persistent tracking with motion prediction, creating an understanding of what objects exist in the environment and how they're moving.

Weight and Size Estimation: A specialized visual processing module enables estimation of object properties based on visual cues. This system analyzes visual features to estimate object size, density, and approximate weight before interaction, providing initial parameters for the force control system before physical contact occurs. This predictive capability allows appropriate force application and grip strength from the first touch, reducing the risk of damage to delicate objects.

Face and Expression Analysis - Social Vision: The ability to recognize and interpret human faces creates the foundation for natural social interaction. The face detection and recognition system identifies individuals and remembers them across encounters, while basic emotion classification enables appropriate responses to human emotional states. Attention direction estimation allows the robot to understand where humans are focusing, enabling more natural conversational behavior and joint attention activities.

Sophisticated audio processing enables natural communication and environmental awareness through a multi-microphone array and advanced processing. This comprehensive audio perception creates a robot that can both hear and understand the auditory environment, from speech to environmental sounds that provide context about surroundings.

Hardware Components - The Ears: The audio input system uses a sophisticated four-element MEMS microphone cluster that provides excellent sound capture with advanced processing capabilities. These omnidirectional microphones feature a signal-to-noise ratio of 65dB and sensitivity of -38dBV, with frequency response from 100Hz to 20kHz capturing the full range of human speech. Integrated acoustic echo cancellation prevents the robot's own speech from interfering with recognition, while active noise suppression improves performance in noisy environments.

Audio Output - The Voice: Sound production comes through a dual 2W speaker system that balances clarity with volume for effective communication. With frequency response from 80Hz to 20kHz and harmonic distortion below 1% at full volume, this system produces clear, natural speech in various environments. Spatial positioning enables directional sound that helps indicate which direction the robot is addressing, while automatic volume adjustment based on ambient noise ensures intelligibility without excessive volume.

Sound-Based Weight Detection: An innovative feature of the audio system is its ability to assist in weight and material estimation through sound analysis. By processing the acoustic signature when objects are placed on surfaces or handled by the robot, the system can provide additional data points for material composition and internal structure estimation, supplementing visual and force-based analysis for more accurate object property assessment.

Speech Recognition - Understanding Speech: The core communication capability comes from sophisticated speech processing that enables natural language interaction. On-device keyword spotting provides immediate response to attention commands, while full speech recognition with local processing ensures privacy and operation without internet connectivity. Speaker identification enables personalized responses to different users, and continuous adaptation to background noise maintains performance across varying environmental conditions.

The AS1 maintains comprehensive awareness of its physical state and interactions through an extensive network of touch, pressure, and position sensors. This sophisticated proprioceptive system creates a robot that truly feels its environment and understands its own body configuration at all times.

Touch Sensing - Surface Awareness: The ability to detect contact and pressure across the robot's body enables natural physical interaction. Capacitive touch panels on forearms and shoulders provide 16 sensing zones per panel that detect not only contact but also pressure estimation through capacitance change. These panels recognize gestures like swipe, tap, and hold, while proximity detection up to 10cm enables awareness of near-contact before touch occurs.

Force-Sensitive Manipulation: The hands incorporate sophisticated pressure sensing for precise object handling. Force-Sensitive Resistor (FSR) arrays with 6 sensing points per hand measure forces from 0.1N to 10N with 10-bit resolution, enabling precise grip control adapted to different objects. Temperature compensation ensures consistent readings regardless of environmental conditions, creating reliable tactile feedback for manipulation tasks.

Load Cell Integration: A network of precision load cells throughout the body provides accurate weight and force measurement for both carried objects and environmental interaction. These calibrated sensors are placed strategically in the feet, hands, and major joints, providing precise measurement of weight distribution, carried loads, and interaction forces. The high-resolution 24-bit HX711 ADCs ensure accurate readings even for small force changes.

Proprioception - Body Awareness: Comprehensive knowledge of body position comes from multi-layered joint sensing systems. Primary magnetic encoders with 14-bit resolution provide precise position data, while secondary potentiometers offer redundant feedback for safety-critical joints. The 9-axis IMU sampling at 1kHz enables real-time balance control through sophisticated sensor fusion for absolute orientation estimation, while strain gauge implementation in critical structural elements enables weight distribution calculation and center of mass estimation.

Additional sensors provide contextual awareness of operating conditions, creating a robot that understands and adapts to its environment. This environmental perception enables appropriate behavior adaptation based on surroundings, enhancing both safety and functionality across varied conditions.

Temperature Monitoring - Thermal Awareness: A distributed network of temperature sensors creates comprehensive thermal awareness across the entire robot. The 24 temperature sensors throughout the chassis monitor both internal and external temperatures with an operating range from -20°C to 125°C and accuracy of ±0.5°C. This system enables thermal management to prevent overheating, safety monitoring of critical components, and environmental temperature estimation for behavior adaptation to different thermal conditions.

Power System Monitoring - Energy Awareness: Comprehensive monitoring of the power system creates complete awareness of energy state and consumption patterns. Voltage sensing on all power rails detects potential issues before they affect performance, while current monitoring enables detailed consumption analysis for optimization. Power state tracking facilitates energy management strategies, and capacity estimation with runtime prediction helps plan operations within available energy resources.

G-Force Monitoring System: A specialized sensing system continuously monitors acceleration forces experienced by the robot to ensure safety and enable adaptive behavior. Using the Bosch BNO085 9-DoF IMU with built-in sensor fusion engine, the system measures both linear acceleration (with gravity removed) and total acceleration (including G-force) with maximum measurable acceleration of ±16g. This data enables detection of falls, slips, or sudden movements, provides input for balance correction and posture stability, and allows measurement of impact force during interaction.

Ambient Condition Sensing - Environmental Context: A suite of specialized sensors monitors the surrounding environment to provide context for operation. The barometric pressure sensor with range from 300hPa to 1100hPa and resolution of 0.1hPa enables altitude estimation and weather prediction, while the humidity sensor measuring from 0% to 100% RH with ±3% accuracy helps prevent condensation issues. The ambient light sensor with range from 0.1 lux to 100,000 lux enables display brightness adjustment and environmental classification.

The AS1's distinctive blue circular lights and arm strips are actually sophisticated micro LCD/OLED displays that transform the robot's exterior into an interactive information system. These displays create a revolutionary visual communication channel that externalizes the robot's internal state, making its awareness, capabilities, and limitations immediately visible and comprehensible to both users and observers.

The blue illumination elements visible across the AS1's body serve as both aesthetic elements and functional displays that communicate system status, sensor readings, and operational parameters. This distributed display network creates unprecedented transparency into the robot's internal state, turning the entire body into an information display that enhances both usability and visual appeal.

Bio-Display Philosophy: The display system represents a fundamental rethinking of how robots communicate their internal state to users and observers. Rather than relying solely on a central screen or verbal communication, the AS1 distributes information across its entire body, showing real-time biomechanical data, local limb state, temperature, joint health, and load conditions directly where they're relevant. This approach creates intuitive understanding of the robot's capabilities and limitations at a glance.

Distributed Information Architecture: The display system creates a multi-level information hierarchy that presents different types of data at appropriate locations. Critical status information appears on the circular displays at major joints, while more detailed diagnostic data scrolls across the strip displays on limbs. This strategic distribution ensures the most relevant information for each body part is presented directly on that component, creating intuitive understanding of the robot's state.

Weight and Force Visualization: A specialized display mode dedicates the bio-displays to visualizing weight distribution, carried loads, and force application throughout the robot. Circular displays show percentage of maximum rated capacity for each joint based on current load, while arm displays scroll actual weight measurements of carried objects. This visual representation creates immediate awareness of the robot's current load state and capacity limitations.

Visual Impact and Function: Beyond practical utility, the display system creates a distinctive aesthetic that communicates the robot's technological sophistication. When in operation, the coordinated information display across multiple body segments creates a living machine aesthetic where internal state becomes externally visible. This transparency transforms AS1 into a readable and reactive entity where engineers can diagnose issues at a glance and observers can intuitively understand what the robot is experiencing.

The circular blue illumination elements located at major joints throughout the AS1's body are actually sophisticated displays that provide detailed status information and diagnostic data for each articulation point. These displays transform joint status into immediately visible information, enhancing both functionality and aesthetic appeal.

Display Hardware: The circular indicators use advanced display technology specifically selected for visibility and power efficiency in a robotics application. Each node uses a 1.3" Round TFT LCD or Round OLED (GC9A01, 240x240px) that provides full-color capability with excellent viewing angle and contrast. These displays connect to the local STM32 limb controller via SPI or I2C interfaces, enabling rapid updates with minimal processing overhead while maintaining visual fluid animation.

Functional Visualization: Each display presents information specific to its location through an intuitive visual language that's instantly comprehensible even to non-technical observers. The primary visual element is an animated ring that serves as a torque load bar, indicating the percentage of maximum capacity currently being utilized by that joint. This dynamic indicator changes color from blue to amber to red as load increases, providing instant visual feedback about stress and capacity.

Load and Weight Indicators: The circular displays provide continuous visualization of forces and weights affecting their associated joints. Numerical readouts show actual torque values and calculated load weight, while graphical indicators display load as a percentage of maximum capacity. These visualizations change in real-time as the robot manipulates objects or experiences external forces, creating immediate awareness of physical interactions.

Enhanced Functionality: Beyond basic status display, these nodes incorporate additional capabilities that enhance the robot's usability. Optional capacitive touch overlays enable the displays to serve as physical interface points for direct robot control, while proximity sensing allows the displays to respond to near-contact by showing additional information when a user's hand approaches. The displays can also serve as localized warning indicators, flashing to indicate excessive load or potential issues in specific body segments.

The elongated blue illumination elements on the AS1's limbs are actually OLED displays that provide scrolling information about limb status, sensor readings, and operational parameters. These displays create continuous information streams that provide detailed diagnostic data and operational metrics directly on the body segments they monitor.

Display Hardware: The strip displays utilize efficient OLED technology optimized for text and simple graphics. Each arm incorporates a 0.91" or 1.5" I²C OLED (SSD1306 or SH1106) mounted in the forearm chassis under a translucent blue diffuser that maintains aesthetic consistency while revealing detailed information. The high-contrast characteristic of OLED technology ensures excellent visibility in various lighting conditions, while the low power consumption minimizes battery impact.

Information Presentation: The displays provide continuous updates on limb-specific parameters through scrolling text and simple graphics. Weight being carried is prominently featured with both numerical values and bar graphs showing percentage of maximum capacity, while motion state indicators show the current operational mode ("Idle", "Gripping", "Lifting"). Additional information includes joint health metrics like servo temperature, voltage, and torque, creating comprehensive awareness of limb condition.

Weight and Force Details: The arm displays provide the most detailed information about objects being manipulated and forces being experienced. When carrying items, the display shows both the measured weight and estimated properties like center of mass and material density. During interaction with resistant surfaces, the display visualizes applied force and encountered resistance, creating awareness of physical engagement with the environment.

Communication Channel: Beyond status display, these strips serve as a communication channel for system alerts and notifications. System message alerts pushed from the LLM core appear on these displays, allowing the robot to communicate detected issues, planned actions, or status updates without requiring verbal communication or central display interaction. This capability creates a secondary communication channel that complements verbal interaction.

Each body segment incorporates a dedicated display management system that controls local visualization while maintaining coordination with the central system. This distributed display architecture ensures reliable information presentation even if individual subsystems experience issues.

Control Hardware: Each limb incorporates a Display Driver Unit (DDU) that manages local displays independently of the main control system. These compact controllers use ATtiny804 or STM32C0 microcontrollers that provide sufficient processing power for display management while minimizing power consumption. Drawing 3.3V from the same buck converter that powers sensors, these controllers maintain display operation even during power conservation modes.

Interface Architecture: The display system uses a hierarchical communication structure that balances local autonomy with central coordination. SPI/I2C connections to the OLED displays provide direct control with minimal overhead, while UART links to the main limb MCU (STM32G4) enable information flow from the central system. This architecture allows displays to continue functioning with local data even if communication with the central system is interrupted.

Weight and Force Display Coordination: A specialized communication protocol ensures that weight and force information is consistently displayed across all relevant bio-displays. When an object is grasped, weight information propagates through the display network to show load distribution across all involved joints, creating a comprehensive visualization of how the weight affects the entire kinematic chain.

Power and Redundancy: The display system incorporates multiple safeguards to ensure continued operation under various conditions. Each display is independently fused and managed to prevent individual failures from affecting the broader system, while failover mechanisms trigger alternative visual signaling using simple status LEDs if the display driver fails. If an entire limb MCU fails, the central Jetson controller can reroute critical limb status to adjacent displays through CAN-broadcast override, maintaining visibility of important information.

The display system integrates fully with the AS1's ROS 2 communication infrastructure, enabling seamless information flow from all subsystems to the appropriate display nodes. This integration creates a unified information architecture where data from any source can be visualized on any display component.

Topic Organization: The display system uses a structured topic hierarchy that organizes information by body segment and display type. Topics like /as1/limb_display/armL carry payload information including object weight, grip strength, and load percentage for left arm displays, while /as1/joint_display/kneeR topics contain joint torque, temperature, and active status for right knee displays. Global alerts and system health information flow through the /as1/display/global topic for distribution to all displays.

Weight and Force Topics: Specialized ROS topics dedicated to weight and force information ensure this critical data reaches displays with minimal latency. These high-priority topics carry calibrated values for displayed weight measurements, force readings, and load percentages, ensuring consistent presentation of physical interaction data across all bio-displays regardless of where the measurements originate.

Customization Interface: The ROS integration includes topics for display customization and configuration, allowing users to modify display behavior for specific applications. These topics enable adjustment of update rates, information priority, color schemes, and visualization styles, creating a customizable information display system that can be adapted to different operational contexts and user preferences.

Data Logging and Analysis: Beyond real-time display, the ROS topics enable recording and analysis of displayed information for performance optimization. All display data can be logged for later analysis, creating a visual record of forces, loads, and system states that complements traditional data logging. This capability enables detailed performance analysis and troubleshooting after operations are complete.

Building the AS1 isn't just about connecting parts—it's about bringing artificial intelligence to life through your own hands. This comprehensive assembly process has been engineered to be accessible while creating a sophisticated platform capable of revolutionary capabilities. The careful integration of weight sensing, force detection, balance systems, and bio-displays creates a unified system where each component enhances the function of the others, resulting in a robot that's greater than the sum of its parts.

Building the AS1 requires specific resources that balance accessibility with capability, enabling construction of a sophisticated robot using equipment available to dedicated enthusiasts. This carefully curated list provides everything needed to create a fully functional humanoid with advanced sensing and display capabilities.

3D Printing Equipment - Fabrication Foundation: The manufacturing process begins with a suitable 3D printer capable of producing structural components with the necessary precision and strength. A FDM printer with minimum build volume of 220 × 220 × 250 mm provides sufficient capacity for all components, while multiple filament capability (dual extruder optimal) enables printing support structures in soluble materials. A heated bed with 100°C capability ensures proper adhesion for technical materials, while 0.4mm nozzles for structural parts and 0.2mm for detailed components provide the appropriate balance of speed and detail.

Electronics Tools - Circuit Construction: Assembling the sophisticated electronic systems requires appropriate tools for component installation and connection. A soldering station with temperature control enables reliable connections without damaging sensitive components, while a precision multimeter with current measurement capabilities facilitates testing and troubleshooting. Additional tools like a logic analyzer or oscilloscope (recommended), wire stripping and crimping tools, and a heat gun for heat-shrink application ensure professional-quality assembly of the complex electrical systems.

Specialized Tools for Force Sensing: The installation and calibration of the weight and force sensing systems require additional specialized tools for optimal results. A precision scale for load cell calibration ensures accurate weight measurement, while a force gauge for FSR calibration enables precise grip force control. The specialized mounting jigs for load cell installation ensure proper alignment and pre-loading, while a signal analyzer for noise characterization helps optimize sensor performance in the completed assembly.

Display Integration Tools: Installing the bio-display system requires tools specific to display handling and connection. Anti-static workstations prevent damage to sensitive display components, while fine-point soldering tips enable connection of the compact display interfaces. Specialized display testing equipment verifies functionality before installation, and display calibration software ensures consistent color representation across all visual elements.

The AS1 is constructed through a modular, progressive build process that ensures each subsystem functions correctly before integration into the complete robot. This methodical approach simplifies troubleshooting and creates confidence in the final assembly by validating each component individually.

Preparation Phase - Foundation Work: The construction process begins with careful preparation of all components and verification of electronic elements. This critical phase includes printing all components according to provided settings, verifying and testing all electronic components before installation, organizing parts by subsystem for methodical assembly, preparing the development environment for software installation, and configuring build tools for custom firmware compilation.

Sensing System Integration: The force and weight sensing components require careful installation to ensure accurate measurements and reliable operation. This phase includes mounting load cells in feet with calibration weights, installing FSRs in gripper surfaces with pressure distribution testing, positioning IMUs with precise alignment for accurate G-force measurement, and calibrating the entire sensing network for consistent measurement across all detection points. This early installation ensures these components are properly integrated into the structural elements.

Lower Body Assembly - The Foundation: Construction begins with the lower body, which provides both structural support and initial weight sensing capabilities. This phase includes constructing the pelvis hub with power distribution components, building hip joint assemblies with primary actuators, assembling upper leg segments with embedded controllers, constructing knee joints with secondary actuators, building lower leg segments with tertiary controllers, assembling ankle complexes with foot plates, integrating load cells and pressure sensors into foot assemblies, and performing initial testing of lower body kinematics and weight sensing.

Upper Body Construction - The Manipulation Center: The torso and arms form the central manipulation system with extensive force sensing capabilities. This construction phase includes assembling the spinal column with torso actuators, constructing shoulder complexes with 4-axis movement, integrating central computing system in torso cavity, installing power management and distribution systems, building arm segments with embedded force sensors and control units, constructing elbow joints with secondary actuators, assembling forearm segments with tertiary controllers and display modules, building wrist complexes with force-sensing hand attachment points, and integrating wiring harnesses through articulation points.

Bio-Display System Installation: The distinctive visual communication system requires careful integration throughout the robot's structure. This phase includes installing circular displays at major joint locations with diffuser overlays, mounting strip displays in limb segments with protective covers, connecting all display driver units to the communication bus, loading display firmware and testing visualization patterns, and calibrating brightness and color consistency across all display elements. This installation transforms the robot's exterior into an information-rich communication system.

The AS1's software stack requires specific configuration for optimal performance, creating a system where sophisticated artificial intelligence works seamlessly with the physical platform. This comprehensive software setup enables all capabilities from basic movement to advanced learning and adaptation.

Operating System Installation - The Digital Foundation: The software infrastructure begins with a carefully optimized operating system environment. The Ubuntu 22.04 LTS base with PREEMPT_RT kernel patches provides deterministic response times essential for robotics applications, while the NVIDIA JetPack SDK with hardware acceleration drivers leverages the full capabilities of the Jetson platform. Custom device tree configurations enable seamless integration of all peripheral devices, while optimized memory and CPU governance ensures consistent performance under varying workloads.

Middleware Configuration - The Communication Layer: The ROS 2 framework provides a sophisticated messaging infrastructure that connects all robot subsystems into a cohesive whole. The ROS 2 Humble installation with custom robotics extensions supports all required functionality, while DDS implementation optimized for intra-robot communication ensures reliable message delivery. Quality of Service profiles for different data categories prioritize critical information like balance and force data, while the topic and service architecture provides a comprehensive control interface.

Weight and Force Processing Setup: Specialized software modules handle the integration and interpretation of the comprehensive force sensing system. Calibration utilities for load cells and FSRs ensure accurate measurements, while signal processing algorithms filter noise while preserving important force variations. The force visualization system maps sensor data to the bio-displays, and weight estimation algorithms combine direct measurement with model-based inference for comprehensive object property understanding.

LegionAGI Framework Deployment - The Intelligence Core: The central artificial intelligence that drives the robot requires careful configuration to leverage the full capabilities of the hardware platform. The process includes LLM model quantization and optimization for edge deployment, sensor integration pipeline configuration to incorporate all data sources, movement control architecture initialization with inverse kinematics setup, behavior tree definition with priority handling, and learning system configuration with baseline establishment. This sophisticated setup transforms raw computing power into an intelligent system capable of learning and adaptation.

Precise calibration ensures optimal performance of all systems, while comprehensive testing validates functionality under various conditions. This methodical verification process ensures that the completed robot performs as expected in all operational scenarios.

Sensor Calibration - Precision Foundation: The accuracy of the robot's perception begins with careful calibration of all sensing systems. Joint calibration sequences establish precise zero positions and range limits, while sensor alignment procedures ensure consistent orientation reference frames across all measurement points. Vision system calibration removes lens distortion and establishes accurate spatial mapping, and force sensor calibration with known weights creates accurate measurement baselines for all load cells and pressure sensors.